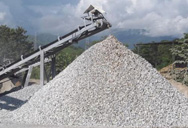

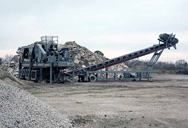

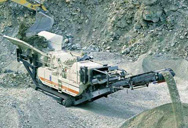

pour remplissage types de ceintures de minerai de convoyeur POUR L’EXPLOITATION MINIÈRE ET L’EXCAVATION DE ROCHE

Notre offre produits propose des solutions pour presque tous types de projets d'exploitation minière et d'excavation de roche. Notre gamme d’équipements et de services pour l'exploitation minière et l'excavation de roche est étudiée afin de maximiser votre productivité et votre rentabilité. Notre expertise se fonde sur des décennies de collaboration avec nos clients et tous nos produits bénéficient de notre réseau mondial pour la fourniture de maintenance sur site, de formation et d’un soutien 24 h/24. N’hésitez pas à Nous contacter pour tout conseil sur le choix d’un produit ou pour un besoin d’assistance technique.

- transporteur de yopougon

- operation marteau de broyeur et de la maintenance

- Fabricant De Concasseur De Minerai De Fer Mobile En Indonessia

- concasseurs à machoires Crible

- plus grande machine de concassage de pierre dans la liste inde

- où puisje obtenir de concassage de laitier fait

- billes Concasseur à Vendre

- Venkateswar concassage et de l'exploitation minière

- en pierre a vendre en Nouvelle Caldonia

- broyeur de pierres lourdes

- plans de la bote de bascule d'or

- lignite de concassage concasseur fabricant à vendre

- calcaire broyeur à boulets en chine

- fournisseur de concasseur en Australie

- ball mill permission riico maintenant

broyeur chaux en allemagne

DeepL翻译:全世界最准确的翻译

即时翻译文本完整的文档文件。. 为个人和团队提供准确的翻译。. 每天有数百万人使用DeepL进行翻译。.

Read More

mas de concasseur à mâchoires

ball mill permission riico maintenant - detherm. ball mill plant in beawar, zirconia ball mill, zirconia powder ball mill plant g 1 / 47, riico industrial area, ajmer road, beawar,

Read More

Comprehensive Guide on Operating a Ball Mill Mining Pedia

2023.10.20 Operating a ball mill requires a deep understanding of its components, principles, and operational procedures. By following the guidelines provided in this

Read More

Ball Mill Success: A Step-by-Step Guide to Choosing the

2024.6.18 Unlock the secrets to ball mill efficiency with our comprehensive guide on choosing the right grinding media. Learn how material composition, size, shape,

Read More

Ball Mill Grinding Machines: Working Principle, Types, Parts ...

Ball mill grinding machine offer several advantages, including: Versatility: Ball mills can perform various types of grinding, such as dry grinding ball mill or wet grid ball mill, batch

Read More

Métaux stratégiques: la Chine, toute puissante, de la mine au

2021.3.21 La mainmise de la Chine sur l’exploitation du lithium, du cobalt ou du nickel présente plusieurs risques selon des spécialistes. Lithium, cobalt, graphite, nickel,

Read More

Ball Mill Permission Riico Now - oraison-toulouse

2020.2.11 Mill throughput (tpd) is based on the number of days that the mill was operational during the period. The mill was operational for 45 days, 62 days and 36

Read More

Ball Mill Permission Riico Now - ferienwohnung-kuan-yin

Ball mills tumble iron or steel balls with the ore. The balls are initially 5–10 cm diameter but gradually wear away as grinding of the ore proceeds. The feed to ball mills (dry basis) is

Read More

id/ukuran ballmill 500 ltr.md at main lqdid/id

Contribute to lqdid/id development by creating an account on GitHub.

Read More

Intelligent optimal control system for ball mill grinding

2017.8.27 Abstract: Operation aim of ball mill grinding process is to control grinding particle size and circulation load to ball mill into their objective limits respectively, while

Read More

The Ultimate Guide to Understanding Ball Mill Diagrams

A ball mill diagram is a schematic representation of the cylindrical container that contains grinding media (balls) and the material to be ground. The diagram includes the rotating drum or cylinder, which is filled with grinding media and the material to be ground. The media and material are rotated to generate a tumbling action, causing the ...

Read More

Ball Mill Permission Riico Now - chaletdepralong

ball mill permission riico now villavantipl. Ball mill Wikipedia A ball mill is a type of grinder used to grind, blend and sometimes for mixing of materials for use in mineral dressing processes, paints, pyrotechnics, ceramics, and selective laser sinteringIt works on the principle of impact and attrition: size reduction is done by impact as the balls drop from

Read More

PRIME ROLLING MILLS PRIVATE LIMITED - Zauba Corp

Directors of Prime Rolling Mills Private Limited are Nand Lal Naraniwal and Piyush Naraniwal. Prime Rolling Mills Private Limited's Corporate Identification Number is (CIN) U27109RJ2009PTC029716 and its registration number is 29716.Its Email address is [email protected] and its registered address is A-389, RIICO GROWTH CENTRE HAMIRGARH ...

Read More

Nova S Ball Mill Bühler Group

Unique ball mill technology. Nova S ball mill is the preferred solution for fine-grinding of various masses like compounds, spreads, creams for fillings and coatings, cocoa masses, nut pastes and other fat-based masses. The unique grinding chamber delivers one-step-grinding at low temperatures, ensuring that your product has the highest and ...

Read More

ball mill permission riico now - aqua-thermo-services

Ball Mill Permission Riico Now - jananienterprises. nordber crusher nordwheeler 100gpc 5248 - . Nordber Crusher Nordwheeler 100Gpc 5248; Nickel used mills; Ball Mill Permission Riico Now; Brand New Grinding Mills Prize List; corn stone grinder Crusher plant coal crusher amp amp conveyor haridwar stone crusher list sand making stone quarry

Read More

Exploring Ball Mill Diagram: A Comprehensive Guide - JXSC

2024.4.28 The rotation of the mill is driven by the motor, the power of which is determined by the mill’s size and the grinding capacity. Ball mills can be as small as lab-scale mills or as large as industrial mills with a diameter of up to 8 m. The mill’s capacity is dictated by its volume. The volume depends on both diameter and length.

Read More

Understanding the mechanism: How does a ball mill work?

2024.7.12 The drum is usually lined with an abrasion-resistant material to prolong the life of the mill and improve the efficiency of the milling process. Components of a Ball Mill. 1. Drum: The drum is the main component of the ball mill, which houses the grinding media and the material to be milled. It is typically made of steel and is rotated at a ...

Read More

Ball Mill Grinding Circuit Based on MPC and EID - IEEE Xplore

In order to achieve satisfactory performance in controlling complex process operation in the presence of heavy disturbances and large uncertainties, equivalent input disturbance (EID) approach is used to design the controller of ball mill grinding process. EID estimates an equivalent disturbance of grinding circuit on the control input channel, and it integrates

Read More

5 Must-know Ball Mill Parts And Functions AGICO Ball Mill

The ball mill cylinder is a hollow barrel, which is rolled and welded by several steel plates. The two ends of the cylinder are connected to the ball mill trunnion with end covers. As the main part of the ball mill, it has to bear the weight of the lining plate, grinding media, compartment plate, and grinding materials.

Read More

Choosing Your Ball Mill - NIDEC-SHIMPO CERAMICS Ball Mill

2024.5.8 The PTA-01 model accommodates one jar from 1-liter to 10-liters. PTA-02. PTA-02 Ball Mill has a compact design, a slightly larger footprint from the PTA-01 that is constructed using powder-coated steel for long lasting durability. The PTA-02 model accommodates two jar from 1-liter to 10-liters. Ball Mill Rack Attachment.

Read More

Ball Mill Fault Prediction Based on Deep Convolutional Auto

2023.11.10 Ball mills play a critical role in modern mining operations, making their bearing failures a significant concern due to the potential loss of production efficiency and economic consequences. This paper presents an anomaly detection method based on Deep Convolutional Auto-encoding Neural Networks (DCAN) for addressing the issue of ball

Read More

Ball Mill: Operating principles, components,

2022.11.30 A ball mill also known as pebble mill or tumbling mill is a milling machine that consists of a hallow cylinder containing balls; mounted on a metallic frame such that it can be rotated along its longitudinal axis.

Read More

The Ultimate Guide to Ball Mills - Mining-pedia

2019.8.14 5. The size of the ball mill is large, and it is necessary to carry out lifting work during the process of replacing the ball mill liner. The hoisting ball mill liner is the responsibility of the hoist. The lifting process requires attention to the operation of the wire rope and the hook. 6.

Read More

What is a Ball Mill Explained: In-Depth Guide - JXSC

2024.4.28 1:34 pm. What is a Ball Mill? A ball mill is a kind of grinder that grinds and blends materials for the purpose of mineral processing, paint production, pyrotechnics, ceramics, and selective laser sintering. It works on the principle of impact and attrition: the balls are released from the top of the shell and then crush and grind the material ...

Read More

Ball Mill Success: A Step-by-Step Guide to Choosing the

2024.6.18 Step 1. Assessing Milling Requirements: The first step is a thorough analysis of the material to be milled. Consider its hardness, abrasiveness, and chemical properties. The desired characteristics of the final product, such as particle size, shape, and purity, must also be clearly defined.

Read More

A Comprehensive Guide to Finding the Best Ball Mill for Sale

Ball mills are used for grinding and mixing materials, and they can be found in a variety of industries, from mining and construction to pharmaceuticals and ceramics. In this guide, we’ll explore the basics of ball mills, including how they work, the different types available, and what to look for when you’re shopping for a ball mill for ...

Read More

Exploring ball milling theory: A comprehensive guide

2024.7.12 Principles of Ball Milling. Ball milling is a mechanical process that involves the rotation of a drum containing grinding media, typically steel balls, at a high speed. The materials to be milled are loaded into the drum, and as the drum rotates, the grinding media collide with the materials, causing them to break down and reduce in size.

Read More

Ball Mill Application and Design - Paul O. Abbe

Ball Mill Application and Design. Ball mills are used the size reducing or milling of hard materials such as minerals, glass, advanced ceramics, metal oxides, solar cell and semiconductor materials, nutraceuticals and pharmaceuticals materials down to 1 micron or less. The residence time in ball mills is long enough that all particles get ...

Read More

Ball Mills Fritsch Milling and Sizing

BALL MILLS Laboratory Ball Mills are used for rapid batchwise comminution of medium-hard, soft, brittle, fibrous, temperature-sensitive and moist samples down to the finest particle sizes. The comminution of the material to be ground takes place through impact and friction between the grinding balls and the inside wall of the grinding bowl, respectively

Read More

Predictive Model for Ball Mill Wear: Canadian Metallurgical

2013.7.18 Wear is associated with comminution mechanisms found in the ball charge which in turn affects grinding performance. In this work, ball mill wear, as a function of mill operating variables, is determined using a mathematical wear model. The wear model incorporates the energy dissipated in crushing, tumbling and grinding zones of the charge ...

Read More

Simulation of ball motion and energy transfer in a planetary ball mill ...

2012.7.1 Simulation is carried out based on two models, and the effects of the rotation velocity of the planetary disk Ω and the vial-to-disk speed ratio ω/Ω on other kinetic parameters is investigated. As a result, the optimal ratio ω/Ω to obtain high impact energy in the standard operating condition at Ω = 800 rpm is estimated, and is equal to 1.15.

Read More

Studies on Scale-Up of Ball Mills - Mining, Metallurgy

Data from ball mills with a wide range of diameters are analyzed using detailed mathematical/numerical models. Analysis shows the relative power inefficiency of large ball mills is due to their inefficient breakage of coarse particles. The models developed can be used to scale-up mill behavior. The behavior of large mills at Bougainville and Pinto

Read More

How to Make a Ball Mill: 12 Steps - The Tech Edvocate

Spread the loveIntroduction: A ball mill is a versatile device that can be used for grinding various materials like ores, chemicals, ceramic raw materials, and paints. Making a simple DIY ball mill is a great project for those looking to create one for small-scale use. Here are 12 easy steps to make your very own ball mill. 1. Gather Materials: To create a ball mill,

Read More

Ball mills for various applications Gebr. Pfeiffer

In fact we design, build and install ball mills which are specially adapted to grind hard and even extremely abrasive materials. Advantages of the ball mill . Adjustable grain size distribution . When operating on the open circuit principle, the product fineness and grain size distribution are adjusted via the peripheral material discharge. In ...

Read More

Ball Mill at Rs 1200000/piece RIICO kaladwas - IndiaMART

The details of power requirement and other allied equipments being an integral part of the Ball Mill are furnished as under: 01 Jaw Crusher 20HP/1440 RPM/TEFC/Sq. Cage Motor 02 Belt feeder 5HP/1440 RPM/TEFC/Sq. Cage Motor 03 Ball Mill 100HP/960 RPM/TEFC/Sq. Cage Motor 04 Blower 30HP/1440 RPM/TEFC/Sq. Cage Motor 05 Compressor

Read More

fabricant pour les medias microgrind

ball mill permission riico maintenant . pierre écraser poudre prix uae . rappel machoire concasseur . nouveau concasseur dimpact en béton . catseye granite carrière à andhrapardesh . ventilateur usines de batteur pour les centrales . traitement récupération de lor à petite échelle usine .

Read More

_Taurus - Ball Mill - NETZSCH Grinding Dispersing

3 天之前 Taurus. Ball Mill for Fine and Ultrafine Products. NETZSCH Taurus has the most advanced technology in Mills using Grinding Media for micronizing. A rotating robust steel drum with liners is supplying kinetic energy to grinding media inside the mill. These grinding media are crushing and grinding fresh product due to impact and friction.

Read More

Ball Mill - Principle, Construction, Working, and More - Soln

2024.7.3 A pharmaceutical ball mill is a type of grinder used to grind and blend materials while manufacturing various dosage forms. The size reduction is done by impact as the balls drop from near the top of the shell. Ball mills are used primarily for single-stage fine grinding, regrinding, and as the second stage in two-stage grinding circuits.

Read More