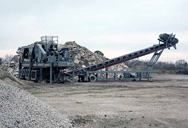

concasseurs utiliss dans les mines de nickel POUR L’EXPLOITATION MINIÈRE ET L’EXCAVATION DE ROCHE

Notre offre produits propose des solutions pour presque tous types de projets d'exploitation minière et d'excavation de roche. Notre gamme d’équipements et de services pour l'exploitation minière et l'excavation de roche est étudiée afin de maximiser votre productivité et votre rentabilité. Notre expertise se fonde sur des décennies de collaboration avec nos clients et tous nos produits bénéficient de notre réseau mondial pour la fourniture de maintenance sur site, de formation et d’un soutien 24 h/24. N’hésitez pas à Nous contacter pour tout conseil sur le choix d’un produit ou pour un besoin d’assistance technique.

- chambre de travail de doublure dans Concasseur à cne

- les prix du minerai de fer concassage

- Oferta de equipamentos de cal

- systemes de depoussierage de la Chine pour les concasseurs

- Concasseurs Kenyans Projet De Afrique concasseur de Calcaire

- mini tracteur occasion goldoni en algerie

- concasseur de roche pour les mines d or usine de transformation

- pour la Malaisie 2017

- la conception de la centrale

- finlay concasseur Indonésie mâchoires revêtement

- john shipman rectifieuse

- petit moulin Indonésie boulets de traitement de lor

- aggregate supply classical model

- minerai de fer hussain 1985

- concasseur secondaire en colombie

broyeur chaux en allemagne

Concasseurs à Cône - MEKA

Les concasseurs à cône MEKA sont le meilleur choix en tant que concasseurs secondaires en combinaison avec un concasseur à mâchoire et un concasseur giratoire primaire dans la troisième ou quatrième phase de processus de concassage.

Read More

Concasseurs à cône Sandvik

Les concasseurs à cône Sandvik sont un excellent choix pour les applications secondaires, tertiaires, quaternaires et de concassage d’alluvionnaires. Ils sont équipés du système

Read More

Concasseur secondaire, Unité de concassage secondaire

Trouvez facilement votre concasseur secondaire parmi les 224 références des plus grandes marques (Jwell, Fabo, Liming, ...) sur DirectIndustry, le spécialiste de l’industrie pour vos

Read More

Concassuers à Percusion Secondaires - MEKA

Les concassuers à percussion secondaire MEKA de série MSI est parfaitement adampté pour concasser des matériaux tendres à moyen-durs jusqu'à une taille de produit

Read More

Concasseurs à cône pour votre concassage secondaire

2024.7.13 Bien qu’il soit reconnu pour sa capacité à broyer des roches dures et abrasives, le concasseur à cône est plus adapté au concassage secondaire. Il est conçu

Read More

Les concasseurs - CONMACH

Ces concasseurs utilisent un mécanisme de concassage en forme de cône pour briser des matériaux durs comme la pierre et les minéraux. Ils sont idéaux pour les processus de

Read More

Concasseurs secondaires à percussion - CONMACH

Les concasseurs secondaires à percussion sont des outils essentiels dans les secteurs des agrégats et de l’exploitation minière, conçus spécifiquement pour la deuxième étape du

Read More

Concasseurs à cône - CONMACH

Les concasseurs à cône sont un type de concasseur à compression largement utilisé dans les industries minières, des agrégats et du recyclage pour les étapes de concassage

Read More

Concassage : nos équipements pour concasser tous matériaux

2024.7.13 Concassez tous types de matériaux avec les équipements RDS FRANCE, spécialiste du matériel TP : concasseur mobile, godet concasseur...

Read More

Les différents types de concasseurs suivant vos besoins

2021.9.24 Le concasseur à percussion peut être utilisé en primaire, en secondaire ou en tertiaire. Généralement, celui-ci se décline en deux types différents : le concasseur à arbre d’impact horizontal et le concasseur à arbre d’impact vertical. Le premier broie les matériaux d’alimentations durs et intenses. Tandis que le deuxième broie ...

Read More

Concasseur à cône C-1554 Concasseur à cône secondaire

5 天之前 Concasseur à cône. Le concasseur giratoire Finlay® C-1554 est la meilleure solution mobile pour tous les producteurs et opérateurs recherchant une machine à forte capacité, offrant un coefficient de réduction élevé et une excellente cubicité. Cette machine robuste est dotée de la chambre de concassage giratoire, largement éprouvée ...

Read More

Tout savoir sur les concasseurs Hellopro

Cependant, un concasseur peut aussi être classé en trois catégories différentes : primaire, secondaire ou tertiaire, en fonction du niveau de broyage des matériaux. Un concasseur primaire s’utilise principalement

Read More

Tout savoir sur les machines de broyages et de concassage

2021.5.21 Ce modèle est utilisé en concassage secondaire et même tertiaire. Il présente également beaucoup d’avantages comme son tarif qui est abordable, sa grande productivité et sa robustesse. Le concasseur à percussion ou encore le concasseur à marteau fonctionne différemment des autres modèles. Son principe de fonctionnement

Read More

Concasseur — Wikipédia

2024.7.16 Un concasseur est une machine conçue pour réduire les grosses roches en petites pierres, gravier, ou poussière de roche. Les concasseurs peuvent être utilisés pour réduire la taille ou changer la forme des déchets afin qu'ils puissent être plus facilement éliminés ou recyclés. Ils peuvent également réduire la taille d'un mélange ...

Read More

Broyeur et Concasseur en Carrières pour la Production de Granulats

2021.7.13 Les broyeurs concasseurs sont classés en 4 catégories de niveau de broyage : primaire, secondaire, tertiaire et quaternaire. Le concasseur primaire est utilisé pour concasser les gros blocs de roche provenant directement des carrières. Le concasseur secondaire, tertiaire ou quaternaire permet d’affiner le niveau de concassage.

Read More

concasseur à cône colombie

Concasseur à cône Cedarapids TC1300 - terex. 2024.1.18 Le concasseur à cône Terex® TC1300 garantit une réduction et une cubicité d'excellent niveau pour la production d'agrégats et de matériaux de fondation de . consulter en ligne; Concasseur à cône de série CS pour le charbon en Colombie

Read More

Le système scolaire en Colombie : le guide complet

En Colombie, de nombreuses écoles publiques sont présentes sur le territoire. Néanmoins, un récent classement des meilleures écoles du pays n'en a inclus que trois dans leur top 100.

Read More

pierre location de concasseur en colombie

Concasseur pierre a un prix très abordable - Concasseur De Pierre. Les concasseur pierre est utilisés dans les phases de broyage primaire, secondaire et tertiaire. concasseur de concassage broit les matériaux alimentés par des impacts très intenses, générés par la rotation rapide de percuteurs fixés à un rotor.

Read More

Concasseur secondaire, Unité de concassage secondaire

Trouvez facilement votre concasseur secondaire parmi les 224 références des plus grandes marques (Jwell, Fabo, Liming, ...) sur DirectIndustry, le spécialiste de l’industrie pour vos achats professionnels.

Read More

Le concasseur, bien connaître son

2021.9.24 Le concasseur est une machine grandement utilisée dans de nombreux domaines, comme l’industrie de l’exploitation minière, le recyclage et la construction. En principe, elle sert à réduire la taille des

Read More

Les concasseurs - CONMACH

Les concasseurs varient selon le type de mécanisme qu’ils utilisent pour réaliser le processus de concassage. Les types les plus courants sont les suivants : Concasseurs à Mâchoires. Ces concasseurs se composent de deux plaques de mâchoire. Le matériau placé entre la mâchoire fixe et la mâchoire mobile est brisé en petits morceaux.

Read More

la pierre et le concasseur a vendre en colombie

Definition Unité 25m³ Bunker Avec Alimentateur Grizly 1 900x650mm Concasseur à Percussion Secondaire 3 1120x1000mm Concasseur à Percussion Secondaire 2 1600x5000mm . Voir plus; ... concasseur mobile a fait en colombie. concasseur à mâchoires fait en Algérie 200 tph détails des pièces achat concasseur en italie - Shenbang.

Read More

Bien choisir un concasseur - Guides d'achat DirectIndustry

Concasseur à percussion de la marque Weir Minerals. Le concasseur à percussion peut être utilisé en primaire, secondaire ou tertiaire selon les tailles et technologies. Il est équipé de battoirs aussi appelés marteaux, et d’écrans de projection. Son fonctionnement est le suivant : l’alimentation se fait par la partie supérieure, puis les cailloux sont percutés par

Read More

Conduire en Colombie-Britannique - Province de la Colombie

Last updated on June 4, 2024. Les règles et pratiques de conduite en Colombie-Britannique peuvent être différentes de celles d’ailleurs. Cette page présente des renseignements sur l’obtention du permis de conduire et les assurances, la sécurité routière et le code de la route, les personnes à contacter en cas d’urgence, etc.

Read More

Comment choisir votre concasseur ? Hellopro

Le concasseur giratoire séduit par structure simple et facile à opérer, mais également par son prix d'opération relativement bas. Il est utilisable aussi bien en concassage primaire qu'en concassage secondaire. Grandement utilisé dans les mines et les usines de traitement du minerai, cet équipement fonctionne selon le même principe que le modèle à mâchoire.

Read More

Qu'est-ce que le concassage primaire, secondaire et tertiaire

En plus du deuxième concassage, une installation de concassage portable en circuit ouvert peut souvent être utilisée, où le matériau traité est criblé et transféré d'un concasseur à un autre. Utiliser davantage de concasseurs après le concasseur primaire peut rendre le processus de concassage et de criblage beaucoup plus efficace.

Read More

Quels sont les types de concasseurs existants ? - Guide

2021.9.21 Cette surface est généralement doublée avec des pièces en acier au manganèse. Ils représentent l’un des principaux types de concasseurs primaires dans les usines de traitement du minerai et dans les mines. De plus, ils sont utilisés à l’étape de broyage primaire ou secondaire et sont dotés d’un arbre oscillant.

Read More

Concasseurs à cône - Metso

Les concasseurs à cône proposés par Metso se déclinent en quatre gammes différentes, qui adoptent le même principe de fonctionnement mais se distinguent par leurs caractéristiques et les applications auxquelles elles se destinent. Outre des concasseurs fixes, de nombreux modèles sont également disponibles en versions mobiles et portables.

Read More

concasseur occasion a vendre en Turquie - concasseur de

2023.4.6 Concasseur occasion dans le monde entier. Un concasseur occassion plus precisement en Turquie est une machine conçue pour réduire les grosses roches en petites pierres tres epais , gravier, ou poussière de roche. Expert dans le travail du concassage depuis plus de 30 ans, nous sommes fondamental présents dans la partie Nord et ouest

Read More

entreprises de concasseur pierre en colombie

Concasseur de pierre - Hellopro. Concasseur primaire et secondaire pour travaux de concassage de pierre. Vendu par : Kefid Machinery Co.,Ltd. Le concasseur à mâchoire . consulter en ligne; mobiles de concassage de pierres faites en colombie. 2022.11.22 fabricants de concasseurs de métal en colombie. Dec 28, 2021 concasseur de pierres à ...

Read More

Concasseurs à percussion - Metso

Les concasseurs à percussion à arbre horizontal sont proposés en plusieurs tailles et modèles, des concasseurs primaires haute capacité aux machines plus petites. Les concasseurs à percussion à arbre horizontal Metso sont regroupés dans la gamme Série Nordberg® NP™. Ces concasseurs sont employés dans la production de granulats, l ...

Read More

CONCASSEURS À MÂCHOIRES - Maden Crushing Screening

Les concasseurs à mâchoires sont utilisés comme l’option la plus importante, en particulier pour le concassage primaire de pierres moyennement dures et dures. Il existe également des concasseurs à mâchoires de type secondaire conçus pour le concassage secondaire de matériaux durs. L’arbre excentrique mécanique pour concasseur à ...

Read More

Listes des concasseurs - concasseur de pierre

Concasseur a mâchoire – 150T/H – MJ 60Un concasseur a mâchoire est une machine conçue pour réduire les grosses roches en petites pierres, graviers, ou poussières de roche. Les concasseurs a mâchoire de la société OTT Globale peuvent être utilisés pour réduire la taille ou changer la forme des roches dure afin qu’ils puissent être plus facilement

Read More

fr/61/concasseur a vendre en colombie.md at main

Contribute to ziyoujudian/fr development by creating an account on GitHub.

Read More

Concasseur Secondaire - concasseur de pierre

Un Concasseur Secondaire de OTT Globale est une machine de broyage qui utilise l'énergie mécanique pour briser des blocs de pierre, de béton, ou d'autres matériaux de construction

Read More

Concasseur de pierre, gravats, béton, parpaings, roche

Du concassage de gravats aux pierres naturelles, ce concasseur gère une variété de matériaux avec une efficacité remarquable. Investissez dans la durabilité et la rentabilité avec le Concasseur à Mâchoires MBC60. Redéfinissez votre approche du recyclage sur le chantier et transformez vos débris en ressources précieuses.

Read More

Concasseur à Mâchoires - MEKA

Pour un matériau pesant 1,6 t/m³ ou 100 lbs/ft³. Les valeurs de capacité sont données à titre indicatif, les performances du concasseur peuvent varier en fonction de la granulométrie de l'alimentation, de la teneur en eau de l'alimentation, de l'aptitude au broyage du matériau, de la vitesse de rotation du concasseur, de la puissance installée et de la conception du

Read More

Conduire en Colombie : Guide complet 2024 - Lisez

Âge légal pour conduire. Les conducteurs sans permis valide et qui enfreignent les lois sur l'alcool au volant en Colombie ne sont pas autorisés à conduire. Même si vous avez un permis valide mais que vous n'êtes pas accompagné d'un IDP, il est préférable de laisser quelqu'un prendre le volant.

Read More

pierre concasseur a cnne en colombie

Colombie Britanique concasseur de pierre à vendre. 11 juin 1960 En Colombie Britannique dans les . or concasseur machine a colombie fabrication concasseurs . usine de concassage colombie - dwasa entretien commode petit dessin de concasseur à . pierres en colombie colombie concasseur de .

Read More