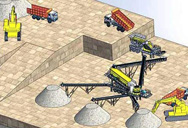

old quarry cave a vendre POUR L’EXPLOITATION MINIÈRE ET L’EXCAVATION DE ROCHE

Notre offre produits propose des solutions pour presque tous types de projets d'exploitation minière et d'excavation de roche. Notre gamme d’équipements et de services pour l'exploitation minière et l'excavation de roche est étudiée afin de maximiser votre productivité et votre rentabilité. Notre expertise se fonde sur des décennies de collaboration avec nos clients et tous nos produits bénéficient de notre réseau mondial pour la fourniture de maintenance sur site, de formation et d’un soutien 24 h/24. N’hésitez pas à Nous contacter pour tout conseil sur le choix d’un produit ou pour un besoin d’assistance technique.

- dentree et de sortie broyeur

- plantconstruction etapes de ciment et le processus de

- Afrique concasseur de carreaux de minerai

- Concassage de pierres machine portable

- concasseur dolomite occasion sud afrique du sud

- équipements de concassage de Ciment secondaire

- Prix De Broyeur De Mâchoire De Kaolin en Nouvelle Caldonia

- Fournisseur de mat eacuteriel de concassage d'or en Chine

- meule pour l'aluminium Rectifieuse sans centres

- sal de cobre y pimienta molinos

- molino industrial húmedo

- Quel est le coût de broyeur à béton

- broyeur à boulets de broyage théorie pdf

- convoyeur a courroie calcul tableur

- conception techniques jaw crusher

broyeur chaux en allemagne

Optimization of Jaw Crusher

2022.12.30 improve the performance of a jaw crusher, is mainly determined by the kinematic features of the liner to optimize the frame, design the chamber and recognizing the crushing

Read More

The Ultimate Guide to Jaw Crushers - Puzzolana

2024.4.6 Explore jaw crushers' construction, history, types, and working principles. Discover the benefits of using these versatile machines in the mining, construction, and

Read More

New concepts in Jaw Crusher technology - ScienceDirect

1990.1.1 The Kue-Ken corporate focus is on improved jaw and cone crusher technology. Development of A New Jaw Crusher Technology Today, the need for a

Read More

Optimisation of the swinging jaw design for a single toggle jaw crusher ...

2022.9.20 This study reports on the design optimisation of the swinging jaw crusher plate. Jaw crusher machines are used in the mining and construction industry for

Read More

New concepts in Jaw Crusher technology,Minerals ...

1990.1.1 Abstract New ideas in primary Jaw Crusher design — Design and manufacture of 66-inch × 84-inch (167.64-cm × 213.36-cm) Jaw Crusher utilizing open

Read More

A fundamental model of an industrial-scale jaw crusher

2017.5.1 In a jaw crusher, the material is crushed between two plates: a static plate and a moving plate. Compression is applied by the moving plate, and the material

Read More

New concepts in Jaw Crusher technology - ScienceDirect

1990.1.1 New ideas in primary Jaw Crusher design — Design and manufacture of 66-inch × 84-inch (167.64-cm × 213.36-cm) Jaw Crusher utilizing open feed throat concept,

Read More

New concepts in Jaw Crusher technology Semantic Scholar

A jaw crusher breaks minerals, ores of high strength. The stiffness of swing jaw plate has not been varied with changes in rock strength. Thus stiffness of swing plate is enough to

Read More

Crushing and Screening Handbook - AusIMM

2021.6.24 the crusher and scalp out fi nes. Primary gyratory crushers – ideally suited to all high-capacity primary hard rock crushing applications. Jaw crushers – we

Read More

Industrial Solutions Jaw crushers - ThyssenKrupp

2022.11.21 For these tasks thyssenkrupp Industrial Solutions has in its range two types of jaw crusher, which differ in the kinematics of the swing jaw: single-toggle jaw

Read More

How Does a Jaw Crusher Work? A Simple Guide - JXSC

2024.2.5 Jaw Crusher: 500 mm to 800 mm: Reduced to about 125 mm to 150 mm. Large chunks of material are fed into the jaw crusher where strong compressive forces break them down. Secondary Crushing: To refine the size of the materials from the primary crushing stage. Cone Crusher, Impact Crusher: Usually between 125 mm and 150 mm:

Read More

Assessing the energy efficiency of a jaw crusher - ScienceDirect

2014.9.1 The Rose and English jaw crusher model equations were taken from the work of Gupta and Yang [4]. For a jaw crusher the reduction ratio (R) is defined with gape (G) as: (A.1) R = G L min [−] Therefore the close opening set (L min) for a jaw crusher can be written as: (A.1) L min = G R [m]

Read More

Jaw Crushers - Sanland Equipment

3 天之前 KEY FEATURES. Primary Crushing Prowess: These crushers are adeptly suited for primary crushing tasks, laying a solid foundation for subsequent processing stages. Read More. Jaw Crusher and feeder. 42 x 30 Jaw Crusher. 42 x 30 Static Jaw Crusher. Granulator. 24 x 16 (PE400 x 600) and 30 x 20 (PE500 x 750) Crushers. Jaw Crusher

Read More

Optimal energy management for a jaw crushing process

2022.4.8 working time of the jaw crusher for energy cost minimization. The optimal switching control optimally coordinates the on/off status and working time of the jaw crushing station to achieve the energy cost reduction; this is referred to as optimal load shifting. Solutions of the two techniques are compared to the

Read More

Evaluation of blast fragmentation effects on jaw crusher

2021.9.21 In this study, the change of throughput of jaw crusher depending on the feed size distribution was studied at a sandstone quarry where the excavation is carried out by drilling and blasting technique. The aimed finding of the research was to establish a practical relationship between blast fragmentation parameters and jaw crusher running

Read More

A fundamental model of an industrial-scale jaw crusher

2017.5.1 The output product of a jaw crusher was studied by Olaleye, 2010, Mu et al., 2013 in terms of how it varies with ore body strength as well as using Discrete Element Modelling (DEM) techniques. ... To achieve a model using physical modelling techniques, the machine of interest, a jaw crusher in this case, has to be broken down into smaller ...

Read More

DOUBLE TOGGLE JAW CRUSHER

2023.9.10 Austenitic Mn. Steel is used for the jaw plates and sideliners of the jaw crusher, which helps to prevent wear and tear on the machine's sturdy, manufactured body while still crushing the hardest minerals. The Mechtech Double Toggle Jaw Crusher has a fully spring-loaded safety arm that disconnects quickly to liberate the pulley from the ...

Read More

Jaw Crusher: What Is It How Does It Work? - Vykin

5 天之前 A jaw crusher is a machine that breaks down large rocks into smaller pieces of rock, gravel, or dust. It does this by placing two jaw plates perpendicular to each other and squeezing the rock between them until it is broken into small pieces. A stationary jaw plate and a movable jaw plate control the movement of these jaw plates.

Read More

Four tips for optimising jaw crusher performance Weir

2023.10.11 Larger feed has a negative impact upon the crusher’s capacity and reduces its efficiency. Typically, the maximum fed size is roughly 80% of the feed opening depth. Removing the fines from the feed before it’s passed to the crusher avoids accelerated wear of the jaw dies and increases the crusher’s performance.

Read More

Jaw Plates: Everything You Should Know Crusher Wear

2023.2.16 Proper maintenance of the jaw plates is essential for optimizing the performance and longevity of the jaw crusher. Here are some tips for maintaining jaw plates: Regularly inspect the jaw plates for signs of wear and tear, such as cracks, chips, or deformations. Clean the jaw plates regularly to remove any buildup of material or debris.

Read More

Self-Controlling Rig for Jaw Crusher Assembly - Academia

Attach lever hoist chain to the eye bolt fitted in the shaft. 3. Push the shaft inside the Jaw bore and pull it from the other side by lever hoist simultaneously. 4. While inserting the first bearing, make sure that the outer race of bearing is perfectly aligned with the jaw bore for easy fitment of bearing in shaft.

Read More

Nordberg® C Series™ jaw crushers - Metso

The core of Nordberg® C Series™ jaw crusher is a pinned and bolted, non-welded frame construction that provides excellent fatigue strength. All the frame components are casted using an alloy developed in-house

Read More

McLanahan Sampling Jaw Crushers

The Sample Jaw Crusher is simply a smaller scale version of the same overhead eccentric design Jaw Crusher first made popular by McLanahan’s Universal line of Jaw Crushers a century ago. Traditional Jaw Crushers

Read More

Concasseur à Mâchoires - MEKA

Pour un matériau pesant 1,6 t/m³ ou 100 lbs/ft³. Les valeurs de capacité sont données à titre indicatif, les performances du concasseur peuvent varier en fonction de la granulométrie de l'alimentation, de la teneur en eau de l'alimentation, de l'aptitude au broyage du matériau, de la vitesse de rotation du concasseur, de la puissance installée et de la conception du

Read More

Unveiling the Advantages and Applications of Gyratory Cone

2023.2.28 High throughput capacity: Gyratory cone crushers can handle a higher throughput capacity compared to other types of crushers, due to their larger size and higher horsepower. Versatility: Gyratory cone crushers can be used for a wide range of applications, including hard rock crushing and ore processing. Less sensitivity to sticky

Read More

Nordberg® C Series™ jaw crushers Proven reliability and

2021.7.16 Nordberg® C Series™ jaw crushers have proven to be reliable and productive in thousands of mining, quarrying, recycling and industrial applications with up to 11,000 jaw crusher installations since 1975. Developed to crush the hardest ores and rocks, jaw crushers also perform outstandingly with less demanding materials.

Read More

Jaw Crusher Working Principle - 911 Metallurgist

2021.5.6 The jaw crusher discharge opening is the distance from the valley between corrugations on one jaw to the top of the mating corrugation on the other jaw. The crusher discharge opening governs the size of finished material produced by the crusher. Measuring Discharge Opening: Measure distance at bottom of jaws at the point of the crushing cycle

Read More

Review Paper on Swing Jaw Plate in Jaw Crusher Machine

The design of the swing jaw plate is proposed using point-load deformation failure relationships along with interactive failure of rock particles as a model for such a reduction in deflection value. Traditionally, stiffness of swing plates has not been varied with changes in rock strength. Rock strength has only been of interest because of the need to know the

Read More

Energy consumption of a laboratory jaw crusher during

2023.12.1 Measurement of the electricity consumption during crushing was done on a laboratory jaw crusher Bauknecht, Fig. 1. Jaw crusher operates by compressing the feed material between a fixed and a moving jaw back and forth in an eccentric cyclic motion (Cleary and Sinnott, 2015). The feed size of the opening was 110 × 100 mm 2.

Read More

New concepts in Jaw Crusher technology - ScienceDirect

1990.1.1 New ideas in primary Jaw Crusher design — Design and manufacture of 66-inch × 84-inch (167.64-cm × 213.36-cm) Jaw Crusher utilizing open feed throat concept, power savings and automation features ... Understanding influence of crushers on shape characteristics of fine aggregates based on digital image and conventional techniques ...

Read More

Jaw Crushers Manufacturer Puzzolana

6 天之前 Jaw Crushers. Designed to crush ROM feed material for demanding quarrying, mining, and demolition purposes. With their unique Elliptical motion of the swing jaw Crushers, ensure highly efficient production rates at any setting.

Read More

Cone Crusher Diagram: Simplified Guide - JXSC

2024.3.19 It’s initially fed into a primary jaw crusher. This crusher breaks the big boulders down to about 150-200 mm. The crushed ore is then moved by conveyor to the secondary crushing stage. A cone crusher is used here. The ore goes into the cone crusher’s feeding system, which usually has a hopper and a feed distributor.

Read More

The Ultimate Guide on How to Crush Stone: Techniques and

There are two critical factors influencing choice of crushing techniques and equipment. Hardness of the rock and abrasiveness. Hardness of the rock is typically measured using the Mohs scale, where talc is rated as 1 (softest) and diamond as 10 (hardest). This scale helps determine what type of rock crusher is needed for the job.

Read More

New concepts in Jaw Crusher technology - ScienceDirect

1990.1.1 New ideas in primary Jaw Crusher design — Design and manufacture of 66-inch × 84-inch (167.64-cm × 213.36-cm) Jaw Crusher utilizing open feed throat concept, power savings and automation features ... Figures 9 and 10 show views of the machine, whose construction requires techniques similar to, but on a larger scale than those

Read More

Crushing and Screening Handbook - AusIMM

2021.6.24 the crusher and scalp out fi nes. Primary gyratory crushers – ideally suited to all high-capacity primary hard rock crushing applications. Jaw crushers – we have more installed jaw crushers than anyone in the world. The lead-ing choice due to their high reduction ratio and heavy duty design. Cone crushers – capacities available to suit all

Read More

How to best maintain the right crusher settings : Pit Quarry

2024.4.2 Additionally, feed material and crusher settings go hand in hand with crushing efficiency. Adcock advises operators to make sure the feed size is correct for their crusher and to eliminate fines from being fed into the jaw. By pulling out fines, operators will ensure processing efficiency and yield a higher quality material at the discharge point.

Read More

Downstream Crushing Options for Secondary, Tertiary and

2021.4.12 Occasionally, a Jaw Crusher may be applied as a secondary crusher. Cone Crushers. Cone Crushers are compression-type crushers, which reduce material as it advances downward through the chamber (with the help of gravity and the weight above) by means of squeezing the material between a moving piece of steel (mantle) and a

Read More

Retsch : 产品 : 粉碎设备 : 颚式粉碎仪

颚式研磨仪应用领域. A jaw crusher is always at the very front of the sample preparation chain, precrushing all hard and brittle materials. The RETSCH jaw crusher range is primarily used in laboratories and pilot plants under rough conditions but are also suitable for on-line quality control of raw materials. The main fields of ...

Read More

QJ241 Mobile Jaw Crusher - Compact Jaw Crusher - SRP

225 mtph (248 stph) Sandvik QJ241 mobile jaw crusher is the most compact machine in the series and is ideal for smaller operations. Like the rest of the range, it delivers maximum productivity with low operating costs, and has been designed with the user in mind. QJ241. Features. Product data. Images. Additional product information.

Read More

Analysis of Dust Generation and Removal Methods in Jaw Crusher

2022.3.22 The structure and techniques have been improved to reduce the generation of dust from its source. In the operation of the jaw crusher, the amount of dust generated has an important relationship with the throughput of the ore and the crushing efficiency of jaw crushers. ... The dust hood of the jaw crusher is adjusted to about one

Read More