montant de broyage Indonésie billes dans l'usine POUR L’EXPLOITATION MINIÈRE ET L’EXCAVATION DE ROCHE

Notre offre produits propose des solutions pour presque tous types de projets d'exploitation minière et d'excavation de roche. Notre gamme d’équipements et de services pour l'exploitation minière et l'excavation de roche est étudiée afin de maximiser votre productivité et votre rentabilité. Notre expertise se fonde sur des décennies de collaboration avec nos clients et tous nos produits bénéficient de notre réseau mondial pour la fourniture de maintenance sur site, de formation et d’un soutien 24 h/24. N’hésitez pas à Nous contacter pour tout conseil sur le choix d’un produit ou pour un besoin d’assistance technique.

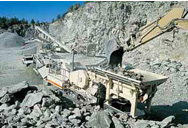

- seconde LM nw main usine de concasseur portable

- salario mineiro de carvão

- dessin isométrique de concasseur Indonésie mâchoires

- broyeurs pour le rock usa

- concasseurs de beton

- inde des couts de l'usineconcasseurs

- Le Moulin Indonésie Marteau De Foudre

- broyeurs occasion raymond à vendre au mexique

- faire une pierre de Gravier de broyage

- usine de concassage carriere au mexique

- inox broyeur à marteaux en acier moringa inde

- portee de concassage de pierres au kazakhstan

- machines de traitement de kaolin porcelaine

- de concasseur mobile fujairah chine

- derniers Minerai de fer equipements dans les usines de granit

broyeur chaux en allemagne

derniers Minerai de fer equipements dans les usines de granit

derniers Minerai de fer equipements dans les usines de granit POUR L’EXPLOITATION MINIÈRE ET L’EXCAVATION DE ROCHE Notre offre produits propose des solutions

Read More

derniers Minerai de fer equipements dans les usines de granit

Notre gamme d’équipements et de services pour l'exploitation minière et l'excavation de roche est étudiée afin de maximiser votre productivité et votre rentabilité. Notre expertise

Read More

MEMOIRE SUR L'INDUSTRIE DU GRANITE

2018.8.9 miante du monde libre. En 1959, par exemple, les expéditions de fibre d'amiante des mines du Québec, qui ont rapporté $100,000,000, se sont élevées a

Read More

Équipements de Minière de Granite - Shanghai Zenith

2024.5.13 SHANGHAI ZENITH fournit non seulement la machine de concassage de granité à vendre aux meilleurs prix, mais aussi le service de l'installation de l’équipement

Read More

Minerais de fer - Aspects géographiques et économiques

Pour la fonte, les minerais de fer sont, à peu près, la seule source ferrifère et, aussi, ne l’oublions pas, pour les minerais réduits (DRI et HBI produits par la « réduction directe »,

Read More

Minerais et fondants : Minerais de fer Techniques de

2011.3.10 Très nombreux, les minerais de fer constituent la matière de base de la sidérurgie. Mais, seulement un nombre limité d'entre eux sont utilisés comme source de

Read More

Le fer : Portrait de la situation - Ressources Mines et ...

Cette même année, les mines de fer exploitées au pays ont produit 47 millions de tonnes (Mt) de minerai à partir de gisements exploités principalement au Québec (51 %), au

Read More

Brésil : pour transporter le fer mondial, ces 890 kilomètres de

Publication 9 nov. 2022, 17:51 CET. À Piquiá de Baixo, les habitants jouent dans une rivière polluée par les usines sidérurgiques des alentours qui traitent le minerai de fer extrait de

Read More

2021, une année déterminante pour le secteur minier africain

2021.1.29 Elle veut investir pas moins de 15 milliards $ pour la construction d’une voie ferrée d’environ 650 km (le Transguinéen) pour le transport du minerai, et d’un port

Read More

Industrie minière: la route du fer Le Devoir

Ensemble, ces sites produisent chaque année plus de 26 millions de tonnes de concentré de minerai de fer, soit l’équivalent de 17 millions de Toyota Prius ou près de 100 000...

Read More

Projet d’Exploitation du minerai de Fer d’Akom II : Les

2023.10.24 Des conteneurs sortis du Port Autonome de Kribi constitués d’un l’assemblage de broyeur mobile industriel d’une capacité de 300 tonnes/heure, appartenant à société de droit camerounais dénommée G-Stones Resources S.A, ont pris, le 17 octobre 2023, la destination de l’Arrondissement de Bipindi, une localité située dans le

Read More

Champion Iron Limited acquiert l’usine de bouletage de

2022.5.17 La compagnie minière Champion a annoncé mardi matin qu’elle fait l’acquisition de l'usine de bouletage de minerai de fer de Pointe-Noire, pour la somme de 2,5 millions de dollars. Par l ...

Read More

Procédés de traitement de minerai Cégep

Cette formation mène à des emplois liés à l’opération, la surveillance et le contrôle de la machinerie et de l’équipement multifonctionnel dans les usines de traitement et d’extraction des métaux et des minerais telles que : - Alumineries. - Usines d’affinage du cuivre, du plomb, du zinc et du fer. - Aciéries.

Read More

Minerai de fer (Fe) Minéraux, Occurrence » Science de la

2023.5.7 Les minerais de fer sont roches ou des minéraux contenant du fer à des concentrations suffisamment élevées pour être extraits de manière économique. Les minéraux de minerai de fer courants comprennent : d'Hématite (Fe2O3): L'hématite est le minerai de fer le plus abondant et le plus important.

Read More

liste composite des équipements de l usine de minerai de fer

11,5 – basique-. La plage exacte dans une usine donnée est optimisée pour le minerai de ce site. La chaux est souvent utilisée pour élever le pH de la pâte et de réduire aussi la flottation de la pyrite de fer. La taille des particules La taille de particule à laquelle le minerai est broyé dépend de la nature du minerai. La

Read More

"Machines de laminoir : Équipements et rôles clés dans la

2024.7.14 Derniers Posts. L’importance des certificats de qualité ISO pour les sociétés d’ingénierie mai 31, 2023; Flokon 6300 : Un mécanisme de haute performance utilisé dans les usines de fer et d’acier mai 16, 2023; Stacker Reclaimer : Traitement efficace des matériaux pour les ports et les industries mai 5, 2023 « Machines de laminoir :

Read More

Gigafactories, usines de production massive : la filière

La mise en route de ce site constitue une étape-clé dans la stratégie de l’équipementier, qui se fixe une capacité de production de 100 000 réservoirs par an d’ici 2030. L’objectif est aussi de réduire par 5 les coûts de production d’ici deux ans. De plus, l’usine répond aux normes environnementales les plus strictes.

Read More

Minerai de fer Québec: plusieurs gains dans les conditions de travail

Sept-Îles, le vendredi 25 juin 2021 – Les 465 travailleurs de Minerai de fer Québec qui travaillent à la Mine du Lac Bloom ont ratifié cette semaine un nouveau contrat de travail de 3 ans, dont 8 mois sont déjà écoulés. Au cours de 4 assemblées tenues cette semaine, les métallos ont entériné l’entente de principe dans une proportion de 79%.

Read More

Analyse de la taille et de la part du marché des équipements de ...

Dans lindustrie de la construction, 90 % de tout le métal raffiné provient de lacier. Cependant, la baisse des teneurs du minerai et les coûts de production élevés entravent la production dans certaines régions du monde. En 2021, le volume total de minerai de fer utilisable produit était denviron 2,6 milliards de tonnes dans le monde.

Read More

fr/derniers équipements de concassage de minerai de fer.md

Contribute to liyingliang2022/fr development by creating an account on GitHub.

Read More

Le fer : Portrait de la situation - Ressources Mines et ...

2020 — volume 6, numéro 5. Le fer : Portrait de la situation. Par Paul Dumas, Géo., MBA. Dans le monde, le minerai de fer est la substance métallique extraite et produite en plus grande quantité. La production mondiale de ce minerai était de 2,4 milliards de tonnes (Gt) l’an dernier comparativement à une production de 1,3 Gt en 2010.

Read More

Minerais : l’Afrique entre positions dominantes et défis

2024.2.5 Une pierre de cobalt extraite en RD Congo (photo AFP). « Les industries basées sur la chimie des batteries pourraient ainsi être viables.. » Les investissements nécessaires dans les usines de fabrication de cellules pourraient être facilités par un soutien aux fabricants nationaux, par de nouvelles découvertes de lithium et par une

Read More

Mine de fer — Wikipédia

2024.7.14 Le minerai de fer est extrait et broyé avant d'être raffiné dans des hauts fourneaux. De nombreux types de minerais de fer sont exploités : pyrite, magnétite, hématite ... L'ensemble du minerai est acheminé à l'extérieur sur la plate forme de travail située à l'entrée de la mine et appelé carreau de la mine. Il est dispersé et ...

Read More

Comment extraire le minerai de fer ? - Edito Matières

Après cela, les tuyaux sont amenés dans la cible, le minerai est broyé avec une pression d’eau puissante suivie d’une extraction supplémentaire. Mais cette méthode a aujourd’hui une très faible efficacité et est assez rarement utilisée. Par exemple, 3 % des matières premières sont extraites de cette manière et 70 % des mines.

Read More

FER - Minerais de fer : Constitution minéralogique et chimique

Les principaux minéraux ferrifères présents dans les minerais sont : la magnétite Fe 3 O 4 (72,4 p. 100 de fer), l'oligiste Fe 2 O 3 (69,9 p. 100 de fer), encore appelée hématite, la goethite Fe 2 O 3, H 2 O (62,8 p. 100 de fer), la sidérite FeCO 3 (48 p. 100 de fer), des silicates et silicoaluminates divers : greenalite, minnesotaïte ...

Read More

Le processus d'extraction dans une carrière de granit

2023.8.29 L'extraction de granit en carrière est complexe et cruciale pour obtenir ce précieux matériau. Nous explorerons les étapes, de l'étude géologique à l'exploitation.Le processus d'extraction dans une carrière de granit est un travail d'envergure considérable et de grande complexité qui joue un rôle crucial dans l'obtention correcte de ce matériau

Read More

Les mines de Batère - Route du Fer dans les Pyrénées

Le grillage est la première étape du traitement par réduction, la seconde étant le martelage du minerai de fer. Cette technique consiste en une modification de sa structure par l’action de la chaleur. L’eau et les matières stériles contenues dans les filons sont brûlées et le volume de matière est réduit d’environ 30% ...

Read More

Minerai de fer – Le Minecraft Wiki

6 天之前 Le minerai de fer est généré en trois groupes : Le premier tente de se générer 90 fois par chunk dans des filons de 0 à 13 [ Java] ou de 0 à 16 [ Bedrock] minerais, entre les niveaux 80 et 384, avec une fréquence maximale autour du niveau 232 et une fréquence moindre vers les deux extrémités de la zone.

Read More

Analyse du minerai de fer - alsglobal

L’analyse géochimique des échantillons de minerai de fer est effectuée par fusion au borate de lithium avec l’ajout d’un agent oxydant suivi d’une analyse par instrument XRF pour les principaux éléments formant des roches et les concentrations sélectionnées d’éléments-traces. Les résultats peuvent être rapportés comme non ...

Read More

Minerais de fer - Aspects géographiques et économiques

2011.3.10 Cet article a pour objectif l'étude des aspects géographiques et économiques de la production des minerais de fer. De nos jours, nous assistons à une croissance rapide de l'offre et de la demande, et donc de la production mondiale. La préparation des minerais de fer a du être réévaluée en fonction de cette évolution, sans

Read More

poster minerai de fer - uliege

2014.1.29 Université de LiègeService de paléontologie animale et humaine. Service de sédimentologie et pétrologie sédimentaire. REGION WALLONNE. Poster réalisé par Julien Denayer Ouvrage de référence: DENAYER, J., PACYNA, D. BOULVAIN, F., (2010): Le minerai de fer en Wallonie: Cartographie, histoire et géologie.

Read More

et broyeurs hpgr dans les usines de minerai de fer usine de granit

et broyeurs hpgr dans les usines de minerai de fer usine de granit POUR L’EXPLOITATION ... Granite (14) Grès (14) Gypse (25) Mâchefer (12) Marbre (15) Métaux de la famille du platine (36) Minerai de fer (45) Nickel (42) Or (46) usines de la taille des particules de minerai de fer et broyeurs. Production mondiale de minerai de fer par pays ...

Read More

Nos Mines ArcelorMittal Canada

2024.7.11 Nos mines. ArcelorMittal Exploitation minière Canada s.e.n.c.est le plus important fournisseur canadien de minerai de fer destiné au marché mondial de l’acier. Active dans les secteurs de l’extraction et de la première transformation, l’entreprise est la plus grande filiale minière du Groupe ArcelorMittal sur le plan international.

Read More

Réduction directe : Dossier complet Techniques de l’Ingénieur

2005.9.10 Ces quatre points constituent les principales parties de cet article qui seront précédées du rappel des bases scientifiques de la réduction des minerais de fer à l’état solide et suivies d’une conclusion sur les avantages, les difficultés et l’avenir de la réduction directe. Cet article est réservé aux abonnés. Il vous reste 92 ...

Read More

Qu'est-ce que le minerai de fer ? - Spiegato

Le minerai de fer est toute roche ou minéral dont le fer peut être extrait de manière économique. Il vient dans une variété de couleurs, y compris le gris foncé, le jaune vif, le violet foncé et le rouge rouille. Le fer se présente sous forme d’oxydes de fer tels que la magnétite, l’hématite, la limonite, la goethite ou la sidérite.

Read More

L’ HISTOIRE DES FORGES ET DES MINES DU BOCAGE ORNAIS - LE SAVOIR LE FER

L’ÉLABORATION DU FER DANS LES BAS FOURNEAUX AU MOYEN-AGE. Le minerai extrait de ces minières était transporté à dos de cheval jusqu’aux forges où il était traité pour produire du fer. Ces forges grossières regroupaient un ou deux bas-fourneaux et plusieurs foyers de forges. Des bas-fourneaux sont attestés dès 1348 à La Ferrière ...

Read More

Minerai de fer Québec Notre entreprise Minerai de fer du Canada de ...

4 天之前 À propos de nous. Fondée en 2016 par l’entremise de la société de développements miniers Champion Iron, Minerai de fer Québec est une entité 100 % québécoise dirigée par des experts d’ici. L’entreprise a été mandatée pour piloter la relance de la mine du Lac Bloom, un projet phare de Champion Iron à Fermont dans le Nord

Read More

Minéraux Formation, Genèse, Occurrence » Science de la

2023.11.8 Minéraux de minerai de placer: Les minerais de placers sont formés par la concentration mécanique de minéraux lourds, tels que l'or, l'étain et les diamants, dans les lits des rivières, les plages et d'autres environnements sédimentaires. Ces minéraux lourds sont généralement transportés par l'eau et triés selon leur densité, ce ...

Read More

Bilan eau dans les usines de traitement de minerais - CASPEO

6 天之前 D’un point de vue plus opérationnel, la diminution générale des teneurs dans les nouveaux gisements exploités entraîne une augmentation des quantités de minerai à traiter et, par conséquent, une plus grande consommation d’eau pour les usines de traitement minéralurgique et hydrométallurgique.

Read More

FER - Minerais de fer : Le commerce international

Le minerai de fer est commercialisé sous plusieurs formes : les morceaux, blocs rocheux, de plus de 40 mm environ (lumps ou calibrés), les fines (0-10 mm) pour agglomération sur grille (ou sinter-feed), les boulettes (10-20 mm) ou pellets, fabriquées à partir de minerais très fins (moins de 100 μm).Le cours de ces produits a considérablement varié depuis la fin du xx

Read More