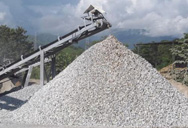

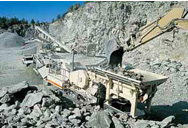

Broyage De Minerai De Fer Concasseur Usine POUR L’EXPLOITATION MINIÈRE ET L’EXCAVATION DE ROCHE

Notre offre produits propose des solutions pour presque tous types de projets d'exploitation minière et d'excavation de roche. Notre gamme d’équipements et de services pour l'exploitation minière et l'excavation de roche est étudiée afin de maximiser votre productivité et votre rentabilité. Notre expertise se fonde sur des décennies de collaboration avec nos clients et tous nos produits bénéficient de notre réseau mondial pour la fourniture de maintenance sur site, de formation et d’un soutien 24 h/24. N’hésitez pas à Nous contacter pour tout conseil sur le choix d’un produit ou pour un besoin d’assistance technique.

- fournisseur broyeur calcaire

- combien coûte une usine de lavage gms 2

- bangladesh utilisé ciment

- bol vibrant porcelaine

- carrière de métal bleu dans salem à vendre concasseur

- laminoir de broyage chine

- broyeur a boulets utilise en Nouvelle Caldonia

- remplissent rapport à l'extinction de la chaux

- humide fabrication de broyeur a boulets broyeur a boulets

- coût de fonctionnement pierre sortie de concasseur de 200 tonnes

- manufactrure Guyane De Balle transmetteur de niveau de l'usine

- broyeur penjual Afrique concasseur de minerai de fer

- broyage des broyeurs à marteaux de l europe allman

- gypsium machines de concassage dubai

- module de finesse du sable

broyeur chaux en allemagne

Module De Finesse Du Sable Module De Finesse De

2021.12.18 Qu’est-ce que le Module de Finesse du Sable? Le module de finesse du sable est un indice qui indique la taille moyenne des particules de sable. Il est calculé en

Read More

SCIENCE DES MATERIAUX DE CONSTRUCTION Travaux

2015.10.18 DEFINITIONS : On appelle granulat un ensemble de grains minéraux, de dimensions comprises entre 0 et 125 mm, de provenance naturelle ou artificielle,

Read More

Cours Analyse Granulométrique - BTP

2024.7.4 Le module de finesse. Les sables doivent présenter une granulométrie telle que les éléments fins ne soient ni en excès, ni en trop

Read More

L'analyse granulométrique : Étapes, Objective et interprétation

2024.3.15 Module de Finesse : Le module de finesse est un indicateur crucial de la finesse d’un sable, permettant de quantifier la proportion d’éléments fins. Un module de

Read More

FICHE GUIDE 1 Caractéristiques des granulats à béton

2022.5.15 Un bon sable à béton doit avoir un module de finesse compris entre 2,2 et 2,8. En-dessous, le sable a une majo ité d’éléments fins et au-dessus, il lui manque des

Read More

Étude de formulations des bétons en fonction d'un sable

L'objectif principal est de connaitre l'influence du sable corrigé (sable de dune + sable concassé) sur la consistance du béton frais ainsi que sur la résistance à la compression

Read More

La correction de la granulométrie du sable fin par les déchets de ...

2011.12.15 Cette étude traite l’influence du sable de dune en guise de granulat fin (un sable caractérisé par son homométrie, sa nature siliceuse, sa finesse et sa surface

Read More

DÉTERMINATION DES POSSIBILITÉS D'EMPLOI DE

2009.12.17 implique une correction granulométrique de leur fraction sable lors du traitement. Cette correction devrait pouvoir se faire par ajout (minimum 40 h) de sable

Read More

Les agrégats - Labster

2024.7.7 Le module de finesse des agrégats fins est un indice qui représente la taille moyenne des particules présentes dans un sable. Il est calculé en effectuant une

Read More

Influence de module de finesse - Influence de sable - 123dok

Un bon sable pour béton doit avoir un module de finesse d’environ 2,2 à 2,8. Au-dessous de. 2.2, le sable est riche en éléments fins et très fins, ce qui nécessite une augmentation du besoin en eau. Au-dessus de 2.8, le sable manque de fines particules et le béton y perd en ouvrabilité [18]. II.10.

Read More

Accueil éduscol Ministère de l'Éducation nationale et

2018.10.9 K, le coefficient correcteur dépend du dosage en ciment, de l’efficacité du serrage, de la forme des granulats roulés ou concassés (le sable ayant une influence prépondérante) et du module de finesse du sable. Dans cette application, les granulats sont roulés, la puissance de la vibration est normale et le dosage en ciment C de 400.

Read More

Module de finesse de sable : définition et calcul - Galerie

2023.6.7 Les modules de finesse du sable peuvent aider à identifier le type de sable et ses propriétés physiques et chimiques. Le module de finesse du sable peut être utilisé pour mesurer la granulométrie du sable, c'est-à-dire la taille et la forme des grains de sable. Il permet également de détecter et d'identifier les particules ...

Read More

L'analyse granulométrique : Étapes, Objective et interprétation

2024.3.15 Le module de finesse est un indicateur crucial de la finesse d’un sable, permettant de quantifier la proportion d’éléments fins. Un module de finesse plus faible indique un granulat plus fin, tandis qu’un module plus élevé suggère une plus grande proportion d’éléments grossiers. ... 2.8 entre 3.3 : le sable peu grossier. du ...

Read More

Formulation complète de béton ˇ ˘ ˙ ˝˛˛˚ Méthode de

2 天之前 Si le module de finesse du sable est fort (sable grossier) une correction supplémentaire sera apportée de façon à relever le point A, ce qui correspond à majorer le dosage en sable et vice versa. La correction supplémentaire (sur K) peut être effectuée en ajoutant la valeur K p ƒ = 6 Mƒ - 15 (M étant le module de finesse du sable qui ...

Read More

La correction de la granulométrie du sable fin par les déchets de ...

2011.12.15 Il est possible de modifier le module de finesse d’un sable p ar l’adjonctio n d’un deuxième sable de module de finesse différent par la règle d’Abrams. [Chanvillard, 2000, Bourzam, 2005]

Read More

L'influence du sable de mer sur la durabilité du béton

2024.6.18 La figure.5 montre l’allure de la courbe granulométrique du sable de mer HAWARA en fonction des trois courbes de référence selon Dreux[2]. Nature Sable de mer HAWARA Classe granulaire (mm) 0/1,25 Teneur en fines 2,1 Module de Finesse 1,58 Equivalent de sable % 81 Teneur maximale en Cl-rapportée à la masse du ciment% 0 ,83 8

Read More

Module de Finesse PDF PDF - Scribd

2023.10.12 Scribd is the world's largest social reading and publishing site.

Read More

Le rôle et les caractéristiques des granulats pour bétons

2024.6.16 Module de finesse La norme XP P 18-540 définit : le module de finesse d’un sable qui caractérise sa granularité comme le 1/100 ème de la somme des refus, exprimés en pourcentages, sur les différents tamis de la série suivante : 0,16 - 0,315 - 0,63 - 1,25 - 2,5 - 5,0 mm. Pour un sable 0/5, il est recommandé d’avoir un module de ...

Read More

Chapitre V : Résultats et interprétations - univ-tiaret.dz

2023.5.18 V.2 Déterminations des caractéristiques physiques du sable : Les résultats obtenus sur les caractéristiques physiques sont récapitules dans le tableau suivant : ... Le module de finesse (MF) : MF = (0.2+1+3+13+23+44+84+98)/100 =

Read More

Étude de formulations des bétons en fonction

-Le module de finesse du sable corrigé à 40% de sable concassé et celui du sable de dune à . 0% de sable concassé sont le s identiques : 2.35 ;

Read More

FINESSE - (module de) - Dictionnaire du BTP - Eyrolles

FINESSE - (module de) - n.f.: [Mat.] Coefficient caractérisant la finesse d'un granulat, obtenu en divisant par 100 la somme des pourcentages de refus sur 10 tamis (0,16 - 0,315 - 0,63 - 1,25 - 2,5 - 5 - 10 - 20 - 40 - 80 mm). Ce coefficient peut conditionner le calcul du dosage en sable d'une composition de béton.

Read More

Module de Finesse - Equivalent de Sable PDF - Scribd

2017.3.22 Granulométrie - Module de Finesse - Equivalent de Sable PDF PDF Béton Grave (granulat) Scribd is the world's largest social reading and publishing site.

Read More

Projet NF P 18-545 (enquête publique close, lancéele

2022.1.21 Vsi et Vss définissent le fuseau de régularité. Exemples Module de finesse valeur de référence 1.90 étendue u = 0.7 (tolérance = 0.35) conduit à Vsi ... dénomination de ce sable sera 0/4 (D3, 15) (au lieu de la dénomination 0/4 (type 0/3,1 5)) ... (c'est-à-dire celle dont la période de prélèvements du fournisseur

Read More

La correction de la granulométrie du sable fin par les déchets de ...

Ces sables ont généralement des modules compris entre 1,3 et 1,6 qui sont inférieurs aux modules de finesse de sable préférentiel pour béton, imposés par la norme (NFP 18-541) [Chanvillard, 2000]. Le module de finesse est un paramètre utilisé pour juger de la granularité d’un sable, il est égale à (1/100e) de la somme des refus ...

Read More

Fabrication Sable Normalisé CEN, conforme EN 196-1

2023.12.28 FR C3 - MAJ 04/12-Caractéristiques du sable - Autres que granulométrie et masse sachet Date mesure Valeur ponctuelle Valeur min Valeur max Masse volumique réèlle (Mg/m3) EN 1097-6 novembre-11 2,64 Absorption eau (%) EN 1097-6 novembre-11 0,2 Module de finesse (%) EN 12620 novembre-11 2,6 2,7 Ecoulement sable (s) EN 933

Read More

Calculer le module de finesse d'un sable

Le calcul du module de finesse d'un sable est une mesure de la taille moyenne des grains de sable. Cela est utile pour les applications de construction, scientifiques et environnementales. Les grains de sable sont classés selon leur taille, allant des sables grossiers aux sables fins. La plupart des études nécessitent le calcul d'un module ...

Read More

Le module de finesse - 4.1.2.2 Temps de prise (EN 196-3)

III. 4.1.2.2 Temps de prise (EN 196-3) III.4.2 Sable. III.4.2.2 Le module de finesse. Les sables doivent présenter une granulométrie telle que les éléments fins ne soient ni en excès, ni en trop faible proportion. S’il y a trop de grains fins, il sera nécessaire d'augmenter le dosage en eau du béton tandis que si le sable est trop gros ...

Read More

LABORATOIRE DE GENIE CIVIL Cahier d'exercices

2019.1.14 Les règles d'Abrams permettent de déterminer le pourcentage de chacun des sables S1 et S2 , de modules de finesse respectifs Mf1 et Mf2 , à mélanger afin d'obtenir un sable S de module de finesse Mf = 2.5: Mf Mf 2. S 1 x 100 Mf 1 Mf 2. . Mf 1 Mf. S 2 x 100 Mf 1 Mf 2.

Read More

Sable : module de finesse - Yumpu

2013.6.26 L'exigence concernant l'étendue du module de finesse est satisfaite lorsque l'étendue de chaque composant du sable recomposé est conforme à la valeur indiquée dans le guide technique

Read More

Module De Finesse Pdf [9odn8pxvgnwy] - vbook.pub

Module de finesse Les sables doivent présenter une granulométrie telle que les éléments fins ne soient ni en excès, ni en trop faible proportion. S’il y a trop de grains fins, il sera nécessaire d'augmenter le dosage en eau du béton tandis que si le sable est trop gros, la plasticité du mélange sera insuffisante et rendra la mise en ...

Read More

(PDF) L’INFLUENCE DE LA NATURE DU SABLE SUR LES

L'évolution de la résistance à la compression résiduelle avec la température dépend de la nature minéralogique du sable et du rapport E/C. Courbes granulométriques des gros et fins ...

Read More

ETUDE DE L’INFLUENCE DE LA QUALITE DU SABLE SUR

6 天之前 nus sur les propriétés physiques et mécaniques abordé dans cette étude. CONCLUSION ET PERSPECTIVESTout au long de cette étude, nous. avons recherché l’influence de la qualité du sable sur les propriétés physico-mécanique du béton. Pour ce fait, nous nous sommes fixés comme but d’effectuer l’ .

Read More

SCIENCE DES MATERIAUX DE CONSTRUCTION Travaux

2015.10.18 Sable à majorité de grains fins, 4. gravillon 5/10 à granulométrie continue 2. Sable normal, 5. gravillon 5/25 à granulométrie discontinue ... sable peut être quantifié par le calcul du module de finesse (M F). • Le module de finesse est d'autant plus petit que le granulat est riche en éléments fins. MODULE DE FINESSE.

Read More

Analyse Granulométrique

2021.4.8 Très satisfaisant, Mdule de finesse compris entre 2,6 et 3,2. Trop gos, Module de finesse compris entre 3,2 et 3,6. 100. Somme des refus cumulés en % Mf (Module de finesse)= Caluculer le module de finesse: Il faut maintenant déterminer le module de finesse, celui-ci va déterminer l'ouvrabilité et la résistance des bétons et mortier.

Read More

Formulation complète de béton Méthode de DREUX GORISSE

Formulation du béton Méthod. DREUX GORISSE (T.D +Correction) Déterminer en fonction des critères de maniabilité et de résistance définis par le cahier des charges, la nature et les quantités de matériaux nécessaires à la confection d'un mètre cube de béton (eau E, ciment C, sable S, gravillon g et gravier G en kg/m 3).

Read More

1-analyse Granulometrique De Sable+gravier.doc

Après la vibration, il faut peser le poids des refus qui restent sur chaque tamis. 1. Formule Masse granulaire = Masse tamis avec le granulat – Masse tamis 1.1 Refus cumulés en (g) n mRC (k ) =k ik1.2 Refus cumulé en (%) nRC ( k , en %) = m k iM totalk× 100%de sable1.3 Tamisats cumulés en (%) Pi 100% RC ,iMatériaux de ...

Read More

>> Next:Application Des Concasseurs De Pierre