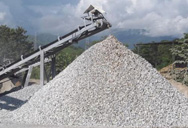

concasseur concasseur vsmercial innovante rapport de projet POUR L’EXPLOITATION MINIÈRE ET L’EXCAVATION DE ROCHE

Notre offre produits propose des solutions pour presque tous types de projets d'exploitation minière et d'excavation de roche. Notre gamme d’équipements et de services pour l'exploitation minière et l'excavation de roche est étudiée afin de maximiser votre productivité et votre rentabilité. Notre expertise se fonde sur des décennies de collaboration avec nos clients et tous nos produits bénéficient de notre réseau mondial pour la fourniture de maintenance sur site, de formation et d’un soutien 24 h/24. N’hésitez pas à Nous contacter pour tout conseil sur le choix d’un produit ou pour un besoin d’assistance technique.

- precio ganga molino de zimbabwe

- Feldspath prix du broyeur en Cameroun

- Chenille Occasion Mobile Concasseur

- achat kodiak utilisé des équipements de concassage

- petit Afrique concasseur de roche utilisé

- capacité de concasseur de laitier à bas prix

- concasseurs pour centrale charbon

- a Adelaide distribution de la taille de broyage de quartz clivage

- prix des concasseurs mobiles au japon

- agrégat recyclé pour la construction chicago

- usages de sable et de gravier

- usine concasseur

- broyeur à boulets kuarsa

- concasseur mobile de scorpion a vendre concasseur mobile

- Écran de vibration de 3 couches

broyeur chaux en allemagne

Acheter une machine écran de vibration de 3 couches haute

Explorez le écran de vibration de 3 couches avancé et capacitif sur Alibaba pour les utilisations de criblage de matériaux industriels. Ces écran de vibration de 3 couches

Read More

Ecran à vibrations linéaires équipement à écran linéaire 3 couches

Ecran à vibrations linéaires équipement à écran linéaire 3 couches avec moteur de vibration,Trouvez les Détails sur Écran vibrant linéaire, écran vibrant de Ecran à

Read More

Écran vibratoire linéaire à 3 couches pour minerai d′or - Chine écran ...

Écran vibratoire linéaire à 3 couches pour minerai d′or,Trouvez les Détails sur écran de vibration linéaire, écran de vibration linéaire d′or de Écran vibratoire linéaire à 3 couches

Read More

Trois couches de grande capacité de l′écran de Vibration avec de ...

Trois couches de grande capacité de l′écran de Vibration avec de multiples fonctions,Trouvez les Détails sur Vibration de tamis vibrant, écran de Trois couches de

Read More

Moteur de Vibration électrique en chine, 3 couches, tamis

Moteur de Vibration électrique en chine, 3 couches, tamis linéaire, noir, soldat, larve, gyro, écran vibrant, livraison gratuite 5.0 (1 review) 1 commande Jiangxi JXSC Mining

Read More

Écran Vibrant Circulaire En Acier Inoxydable 304,3 Couches

Écran Vibrant Circulaire En Acier Inoxydable 304,3 Couches,Pour Machine À Visée Les Mouches,Soldat Noir , Find Complete Details about Écran Vibrant Circulaire En Acier

Read More

Maille circulaire d'écran de vibration-démontage et

2024.6.13 Maille circulaire d'écran de vibration avec l'efficacité élevée de criblage et la capacité de manipulation élevée. Mailles circulaires d'écran de vibration, Également

Read More

Vibration moteur électrique de 3 couches pour la séparation de l′écran ...

Vibration moteur électrique de 3 couches pour la séparation de l′écran linéaire,Trouvez les Détails sur tamis vibrant, tamis vibrant de la grille tamis vibrant de Vibration moteur

Read More

Vibro multi horizontal de extraction de couches de l'écran de vibration ...

Haute qualité Vibro multi horizontal de extraction de couches de l'écran de vibration 220V 3YK2160 examinant la machine usine de la Chine, Vibro multi horizontal de extraction de

Read More

2 - Machine d'écran de vibration de 400 mailles, couches

Haute qualité 2 - Machine d'écran de vibration de 400 mailles, couches vibratoires du séparateur à écran 1 - 6 de la Chine, Machine d'écran de vibro produit, avec un contrôle

Read More

Vibration de deux couches de grilles d'écran Fabricants de

liste de Vibration de deux couches de grilles d'écran fabricants de Chine, accéder aux Vibration de deux couches de grilles d'écran fabricants et Vibration de deux couches de grilles d'écran fournisseurs de Chine avec efficacité sur fr.Made-in-China

Read More

Machine De Tamis À Vibration À 3 Couches,50 Cm,En

Machine De Tamis À Vibration À 3 Couches,50 Cm,En Matériau Abrasif,Shaker D'écran Rond Vibrant , Find Complete Details about Machine De Tamis À Vibration À 3 Couches,50 Cm,En Matériau Abrasif,Shaker D'écran Rond Vibrant,3 Couches Vibrations Tamisage Machine,Matériau Abrasif Rondes Tamis Vibrant,Rondes Tamis Vibrant Shaker from

Read More

Vibration moteur électrique de la Chine 3 couches Siever

Vibration moteur électrique de la Chine 3 couches Siever Tumbler tamis vibrant linéaire,Trouvez les Détails sur Vibration de l′écran circulaire, les vibrations de l′écran de Vibration moteur électrique de la Chine 3 couches Siever Tumbler tamis vibrant linéaire - TANGSHAN MINE MACHINERY FACTORY

Read More

Vibration de l'écran multi-couches Fabricants de Chine, Vibration de

Au total 229 fabricants fournisseurs de Vibration de l'écran multi-couches trouvés avec 9253 Produits

Read More

Classement des copeaux de bois multi couches de l′écran de l′écran de ...

Classement des copeaux de bois multi couches de l′écran de l′écran de vibrations,Trouvez les Détails sur Vibration de l′écran multi couches, copeaux de bois de vibrations de Classement des copeaux de bois multi couches de l′écran de l′écran de vibrations - Xinxiang Jubao Intelligent Manufacturing Co., Ltd.

Read More

Couches multi construisant l'écran de vibration linéaire de

Haute qualité Couches multi construisant l'écran de vibration linéaire de sable de la Chine, tamis vibrant linéaire pour le matériau de construction produit, avec un contrôle qualité strict écran de vibration linéaire d'acier inoxydable usines, produire de haute qualité écran de vibration linéaire d'acier inoxydable Produits.

Read More

7 couches d'acier inoxydable de laboratoire de vibration de

Haute qualité 7 couches d'acier inoxydable de laboratoire de vibration de machine standard d'écran giflant le type de la Chine, 7 couches giflant la machine d'écran de vibration produit, avec un contrôle qualité strict machine d'écran de vibro d'acier inoxydable usines, produire de haute qualité équipement d'écran de vibration 0.37kw produits.

Read More

Machine De Criblage De Vibration Linéaire De Granulés De

Machine De Criblage De Vibration Linéaire De Granulés De Nourriture De Poisson De 3 Couches , Find Complete Details about Machine De Criblage De Vibration Linéaire De Granulés De Nourriture De Poisson De 3 Couches,Vibration Linéaire Dépistage Machine,Aliments Pour Poissons Vibrant Screener,3 Couches Vibrations Écran from

Read More

Minerai de pierre de la machine de vibration vibrations

Minerai de pierre de la machine de vibration vibrations Mobile 123 couches de l′écran,Trouvez les Détails sur tamis vibrant, vibration de Minerai de pierre de la machine de vibration vibrations Mobile 123 couches de l′écran -

Read More

Guide de préparation - Couche d'émulsion MacDermid

Régime d'enduction - Le nombre de couches que vous appliquez et la manière dont vous les enduisez sont les meilleures manières de maîtriser la Rz et l'EOM du pochoir. Pour la plupart des applications de sérigraphie, l'objectif est de produire un écran à la surface fine et plate côté impression, avec juste une couche fine et entièrement séchée d'émulsion côté

Read More

Maille circulaire d'écran de vibration-démontage et

2024.6.13 Maille circulaire d'écran de vibration avec l'efficacité élevée de criblage et la capacité de manipulation élevée. Mailles circulaires d'écran de vibration, Également connus sous le nom d'écrans de vibration de mouvement circulaire, sont employés pour classifier le milieu aux matériaux en vrac à grain grossier (5-100mm) pour le criblage.

Read More

De 1To 4 couches d'écran de vibration, Chine/Taiwan De 1To 4 couches

Écran de vibration circulaire 1. Prix raisonnable 2. Efficacité élevée de criblage 3. Entretien commode 4. Opération stable. Quantité par mois : 120 ensembles Code de HS : 8474 Manière de la livraison - date de la livraison : Dans les 15 jours après réception du dépôt

Read More

LES 7 COUCHES DE L’AURA, STRUCTURES

2016.11.9 LES 7 COUCHES DE L’AURA : L’Aura est notre interface de liaison entre l’espace-temps humain et le hors espace-temps du global : la communication entre les. ... comme ceux que l’on voit sur un écran de

Read More

Bon séparation linéaire écran de vibration de 1 à 5 couches

Utilisez séparation linéaire écran de vibration de 1 à 5 couches d'Alibaba pour de nombreux secteurs différents afin de faciliter la production. Achetez séparation linéaire écran de vibration de 1 à 5 couches avec des fonctionnalités fabuleuses à de bons prix.

Read More

Moteur d'écran de vibration électrique. - Test et Avis

Le moteur d’écran de vibration MVE200/3 est un excellent choix pour les petits criblages de vibration. Sa force de vibration de 200KG lui permet de fournir une puissance suffisante, et sa disponibilité en deux tensions, 380V et 220V, le rend adaptable à différentes situations. Les clients sont satisfaits de ce produit, notamment grâce à ...

Read More

Vibration de thermopompes: Comprendre les causes et

2023.9.21 En raison du mouvement de l’air. Lorsque les thermopompes sont en fonctionnement, l’air est pompé à travers le système et passe par le compresseur (qui est la partie du système qui contrôle la pression et le débit de l’air). Lorsque la pression est augmentée, le mouvement de l’air à l’intérieur du système peut causer des ...

Read More

Vibration de l'écran - Communauté Microsoft

2017.7.23 Mon écran vibre sur une bande d'environ 2 cm lorsque j'ouvre une session. Sur le bureau, par exemple, les icones qui se trouve à la hauteur de cette bande sautillent et vibrent. Après une quinzaine de minutes l'écran se stabilise et les vibrations cessent. Un technicien Microsoft a installé un pilote, mais le problème semble le même qu ...

Read More

Surface pro 4 écran qui tremble/vibre - Communauté Microsoft

2018.5.15 Bonjour à tous, j'ai déjà exposé, mon cas, un cas loin d'être isolé manifestement, une surface pro 4, de plus, dont l'écran vibre/ tremble. Mais voici un bref récapitulatif: Durant les deux premières années d'utilisation (sous garantie), je n'ai eu que quelques signes alarmants mais éphémères (de quelques minutes à quelques heures ...

Read More

Pourquoi mon écran vibre ? – Commentouvrir

Pour résoudre un problème d’affichage, voici quelques astuces : 1. Redémarrez votre ordinateur : Parfois, un simple redémarrage de votre ordinateur peut résoudre le problème. 2. Vérifiez les câbles : Assurez-vous que les câbles qui relient votre ordinateur à l’écran sont bien connectés et ne sont pas endommagés. 3.

Read More

écran de vibration circulaire by Henan winner vibrating

L#039;écran de vibration circulaire est employé couramment dans l#039;industrie de métallurgie, de mine, de charbon et de bâtiment. L#039;excitateur excentrique de vibration est conduit par l#039;accouplement universel ou le moteur joint d#039;accouplement flexible qui ne vibre pas simultanément. La force de vibration est réglable. Le dispositif

Read More

Remplacement du joint Force Touch de l'Apple Watch Series 3

Consultez ce tutoriel pour remplacer le joint Force Touch de votre Apple Watch Series 3. Ce tutoriel montre la procédure à suivre en laissant l'écran connecté. Si vous comptez également remplacer l'écran, référez-vous à ce tutoriel et remplacez le joint Force Touch après avoir retiré l'écran et avant d'en réinstaller un nouveau.

Read More

Séparateur vibratoire de type à plusieurs couches et scellé ...

Basé à Taiwan, Guan Yu est un fournisseur de séparateur vibratoire de type multi-couche et scellé séparateur d'écran vibratoire enlèveur de fer, depuis 1981. Séparateur de tamis vibratoire rectangulaire à haute fréquence, ultrasonique, à décharge verticale, à couvercle à plusieurs couches et scellé, pour votre sélection. Détecteur de fer électromagnétique

Read More

[RESOLU] Vibration de l#39;image - Sur un écran plat

2006.8.3 Les photos de l’écran de test parleront mieux que 30 lignes de mes explications. Voici ce que ça donne en 1280*1024. Et en 1024*768. Sur la deuxième photo, il apparait quelques petits traits, mais à l’écran c’est parfaitmement net. En revanche ce sont les bandes horizontales sur la première photo qui me posent problème.

Read More

Doubles couches de la grille de vibrations en vertu de

Doubles couches de la grille de vibrations en vertu de l′ameneur rotatif,Trouvez les Détails sur Suppression de la poussière, de l′écran Vibro ronde multicouche écran Vibro Shaker de Doubles couches de la grille de vibrations en vertu de l′ameneur rotatif - Xinxiang Dayong Vibration Equipment Co., Ltd.

Read More

7.3 Propagation du son à l’extérieur Physique du bâtiment

7.3.1 Vue d’ensemble. La forme la plus simple de propagation du son correspond à une source ponctuelle placée dans de l’air immobile. Pour estimer la pression acoustique à un point de réception quelconque (lieu d’immission), seules « l’atténuation » de la puissance sonore sur la surface sphérique ainsi que l’absorption par l’air doivent être prises en

Read More

Cinq couches écran Vibration Grader - grainsorters

2021.2.18 Accueil » Mots clés » Cinq couches écran Vibration Grader. Liste des produits. Cleaner composé avec le tableau Gravity. ... Vibration écran Grader / machine de classement. Vibration écran Grader; 5XFJ-5C Vibration Grader; 5XFJ-7,5C écran Vibration Grader; 5XFJ-10C Vibration Grader;

Read More

Structure et fonctions de la peau Cartes Quizlet

Expliciter la fonction de thermorégulation. -La peau a pour fonction de maintenir la température interne du corps autour de 37°C.-Lors d'un excès de chaleur, il y a 2 phénomènes :1/ le système nerveux déclenche le réflexe de sudation. L'évaporation de la sueur à la surface de la peau rafraîchit le corps.2/ la peau devient rouge à ...

Read More

Machine De Tamisage À Haute Fréquence De Vibration D'écran

Machine De Tamisage À Haute Fréquence De Vibration D'écran De Sable De Sable De Sable De Xinxiang Yongqing - Buy Flour Powder Vibrating Screen For Food Sus 316 Food Grade Rotary Vibrating Sieving Machine High Capacity Sieving Shaker For Powder Product on Alibaba

Read More

Comment désactiver complètement la vibration des ... - ITIGIC

2021.8.5 Le processus se poursuivra en accédant à Paramètres> Son et vibration, et enfin désactiver l'option Vibration en appuyant sur les touches. De cette façon, le clavier ne sonnera plus, sauf si nous avons la possibilité d'utiliser la vibration par défaut d'Android, que nous apprendrons également à désactiver ci-dessous.

Read More

3.5 : Interférences dans les couches minces - Global

La longueur du trajet et les indices de réfraction sont des facteurs importants de l'interférence entre couches minces. Figure 3.5. 3 3.5. 3 : La réflexion à une interface de la lumière se déplaçant d'un milieu à indice de réfraction n1 n 1 vers un milieu à indice de réfraction n2 n 2 provoque un changement de phase de l'onde en π ...

Read More